Made in East Sussex: Enigma Bikes

Before the 1980s the UK was home to the inventors, the innovators, and the global custodians of high-end bike manufacturing. If you owned a bike back then in this country the chances are it was British-made. Fast forward to today, in an era of intense global competition and it’s reassuring to discover that one of the UK’s leading bike manufacturers and finest producers of titanium hand-built frames, Enigma Bikes, is reviving the nearly lost art of frame building at its East Sussex facility.

Enigma Bikes

East Sussex is a well-known destination for great cycling, from the Cuckoo Trail that runs from Eastbourne to Heathfield through 14 miles of beautiful Sussex countryside to the Coastal Culture Trail along the seafront from Hastings to Eastbourne via Bexhill. And, let’s not forget the annual London to Brighton event. So, it shouldn’t be a surprise to know that located on the edge of Sussex Downs National Park trail, lies Enigma Bikes, occupying 8000 sq ft of workshop space in the historic market town of Hailsham. Enigma specialises in high-end design and manufacturing of tailor made titanium frames.

Clients from all over Europe, the United States, and even as far as Singapore, visit Enigma’s showroom and workshop for a personal and professional fitting. They get to witness all the different stages and processes involved in frame construction and finishing. On display in its showroom are Enigma’s range of bike models, components and accessories for customers to see, touch and feel, and to design the all-important unique aesthetic finish for their new bike.

They all share a meticulous attention to detail, they’re passionate about craftsmanship. They all love bikes, love to ride and strive to give the best customer service

‘The whole custom build and finish process is a collaboration between us and the rider’, says founder and director of Enigma, Jim Walker, self-confessed perfectionist and respected veteran of the industry. The Enigma story started 10 years ago, when Jim, having sold his successful distribution business in 2006, decided to further indulge his passion for beautiful bikes and founded Enigma. Jim has a passion for ‘classic and timeless’ design and Enigma is the ultimate embodiment of his desire to build beautiful bikes here in Britain. He still rides whenever he can on a replica version of his first ever-bike, a present from his team…probably the most talented team of bike building experts in the UK. His love of simply riding his bike is as strong today as it ever has been.

Built to order to the customer’s exact specifications and made one at a time, a custom-made bike is a meticulous work meaning Enigma currently produce around 600 frames a year. ‘It is a thing of personalised beauty’ said Christine Walker, Enigma’s Finance Manager and Jim’s wife. Christine is just as passionate about the business as Jim (although she admits she prefers to drive). Jim and Christine are constantly impressed by the skill, commitment and ingenuity of the individuals who make up the Enigma team. Jim’s perfectionism is unparalleled and he can spot a minor problem from twenty yards away. ‘But, they all share a meticulous attention to detail, they’re passionate about craftsmanship,’ Christine told us. ‘They all love bikes, love to ride and strive to give the best customer service.’

One such happy customer, Karen, a keen cyclist, approached Enigma after an operation following a car accident, which left her with greatly reduced mobility limiting her riding abilities. The team designed and built for her a custom made titanium bike that took her injuries into account. ‘The idea is to find out somebody’s ‘body geometry’, which is everything from the length of your bones to the level of mobility’ Jim said. ‘That information enables us to know exactly what size to make the bike, with precision distances between parts to make sure the person is as comfortable as possible.’ Karen was thrilled with the results which meant she was able to maintain her quality of life and continue to ride in comfort.

The idea is to find out somebody’s ‘body geometry’, which is everything from the length of your bones to the level of mobility.

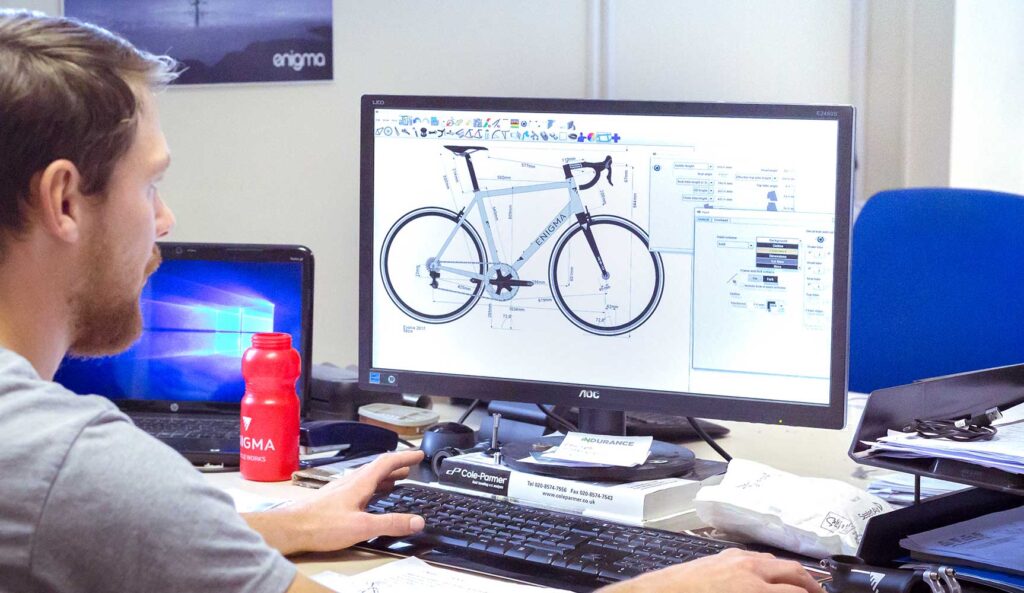

Used in the aerospace industry, titanium, is a mysteriously lightweight metal, yet strong and versatile, and one of hardiest of materials to work with, but a lifetime frame material. Each frame is painstakingly handcrafted, from Joe (Walker), Jim’s son’s expert tig welding, Jaco’s incredible seamless paint finishes to Richard’s C.A.D designs. It isn’t a factory line, it’s a studio of artists with health and safety signs. Even an inexperienced cyclist with little knowledge would be hard pushed not to be impressed by the precision mitring and almost invisible welding (they’re all that good).

UK’s first frame building apprenticeship

However, Enigma knows that there is no future for its craft if the traditional skills are not passed to a new generation. They are passionate about training apprentices to ensure manufacturing skills aren’t lost to the Far East. Sam, their current apprentice, recently completed the first-ever frame building apprenticeship in the UK with Sussex Coast College, part of the East Sussex College Group. A natural talent, Sam’s academic qualifications would have enabled him to choose almost any career path. Luckily for Enigma, Sam wanted to work with his hands and has chosen the creative, practical side of the bike industry with Enigma.

How we helped Enigma Bikes

Since 2014, with funding from East Sussex County Council and support from Locate East Sussex, Enigma Bikes now carries out every aspect of the frame and bike build from initial consultation, frame design, the build process itself right through to the final frame finishing on the premises. A new paint room, cutting/mitre machine and a purpose made fork jig were introduced. In total, Enigma has increased its workforce by five employees. Recently, with further investment Enigma created a specialised fitting room to increase space for production and to expand its showroom. Enigma now plan to add to their portfolio a range of carbon fibre frames in the near future.

Image Credits: Caitlin Lock